Komatsu Smart Construction enhances manufacturing process to offer industry-first bespoke excavators

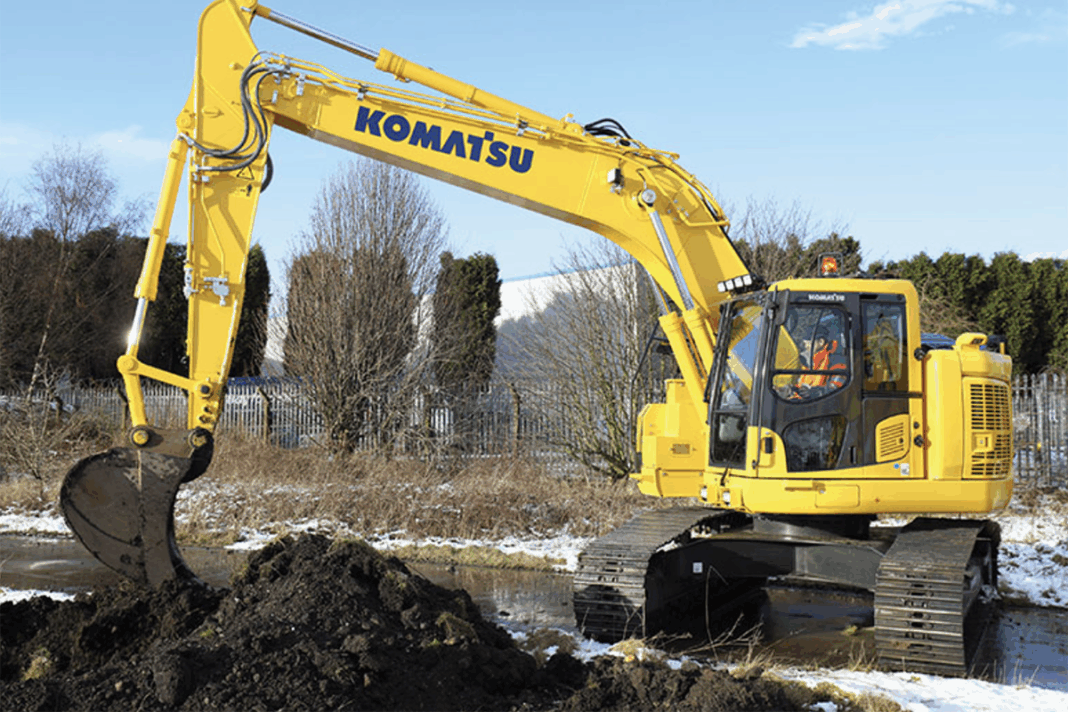

Smart Construction, the digital arm of global Japanese manufacturer Komatsu, has announced it is enhancing the manufacturing process of the iconic excavator range to offer the first ‘bespoke’ machine from the factory.

The latest announcement by the European team will launch a new ‘fitted at the factory’ process, set to revolutionise the manufacturing of Komatsu’s PC240 and PC228 crawler excavator models.

Smart Construction 3D Machine Guidance, which was previously retrofitted locally or in the field, will now be fitted during the machine assembly at the factory – offering a fully bespoke, digital-first machine.

This innovation makes Komatsu the first Original Equipment Manufacturer (OEM) to develop its own guidance and control products installed at the factory before the equipment is delivered to customers.

Driven by its key brand values spanning efficiency and digitalisation, specialists will complete the installation of the additional hardware on the assembly line, removing pressure from distributors.

Bart Vingerhoets, Senior Commercial Manager at Komatsu Smart Construction, commented: “With installation now taking place at the factory, Komatsu Smart Construction is proud to expand the capabilities of its technology-fitted excavators, set to support the digitalisation of the construction industry, both for today’s jobsites and those of the future.

“Thanks to our vertically integrated manufacturing approach, fully developed and supported by Komatsu and its distributors, we can offer this top-tier technology at cost-effective pricing, making it more accessible for the industry.”

“The launch of a fully bespoke GPS guided excavator is set to be welcome across the sector, as the industry requires streamlined and effective machinery to operate efficiently, especially in light of the current skills shortage in the industry.”

The new ‘fitted at the factory’ technology will enable both PC228 and PC240 crawler excavators to be in the field for the maximum amount of time – avoiding downtime during retrofitting post-delivery.

Bart adds: “Our aim is clear – to make more machines digitally native, enabling richer data collection and giving customers greater access to actionable digital insights that drive smarter, more efficient operations.”

For more information, please visit: smartconstruction.io