The opening of the first dedicated Fuel Cell Test Lab in Volvo Group, marks a significant advancement in the manufacturer’s ambition to be fossil-free by 2040.

Volvo CE takes big step towards a carbon neutral future with hydrogen Fuel Cell Test Lab

As part of the company’s commitment to the Science-Based Targets initiative – a necessary measure to meet the goals of the Paris Agreement – and the Group’s long-term ambition to be 100% fossil-free by 2040, this pioneering investment will offer Volvo Group unique conditions to test and develop hydrogen fuel cell technology solutions in heavy construction machines and other applications.

The dedicated lab, located at the Volvo Construction Equipment (Volvo CE) Technical Center in Eskilstuna, Sweden, represents a big step forward in the company’s commitment to hydrogen. The lab is also the first facility in Volvo Group to be testing complete fuel cell units, and will as such be a strong contributor to the company’s dedication to fuel cell technology.

Toni Hagelberg, Head of Sustainable Power at Volvo CE, says: “Fuel cell technology is a key enabler of sustainable solutions for heavier construction machines, and this investment provides us with another vital tool in our work to reach Science-Based Targets. The lab will also serve Volvo Group globally, as it’s the first to offer this kind of advanced testing. It’s a really exciting step to accelerate the development of fuel cell solutions towards our united vision for a carbon neutral society.”

Fueling an emission-free world through hydrogen

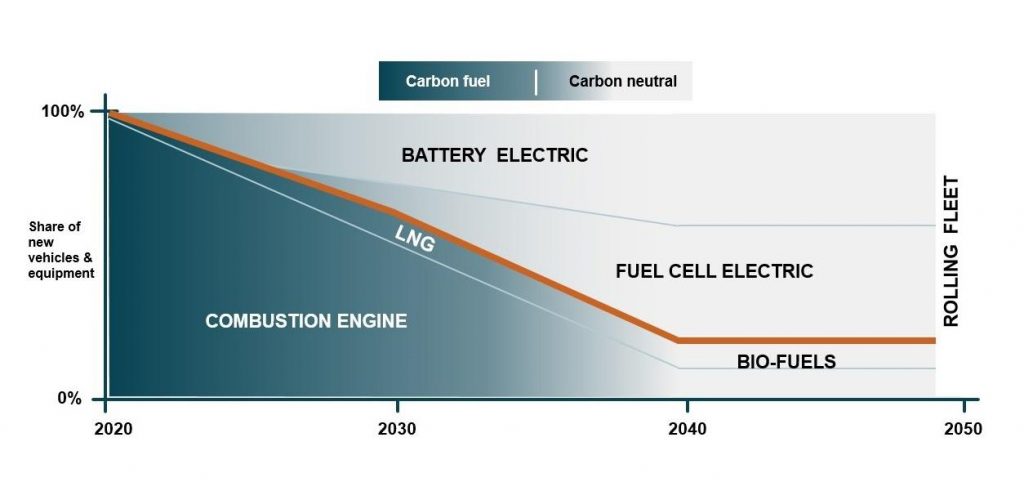

Volvo CE sees hydrogen fuel cell technology as playing a key role within its overall electromobility ambitions, together with battery electric solutions, as demonstrated by the electric compact machines, and more sustainable internal combustion engine offerings – with all three streams working in alignment on the journey towards a carbon neutral society. While battery electric solutions are ideal for urban construction and other use cases, the size of the batteries is simply too impractical for larger machines and heavy construction equipment, which is where hydrogen comes in as a promising alternative.

“Hydrogen can be produced in many different ways and it’s important to have a life-cycle approach across the entire value chain”, says Hagelberg. “Not only will the research and development carried out at the test lab be dedicated to producing fossil-free construction solutions, we will also look at how the hydrogen itself has been produced, and strive for so called “green” hydrogen produced from renewable energy.”

How it works

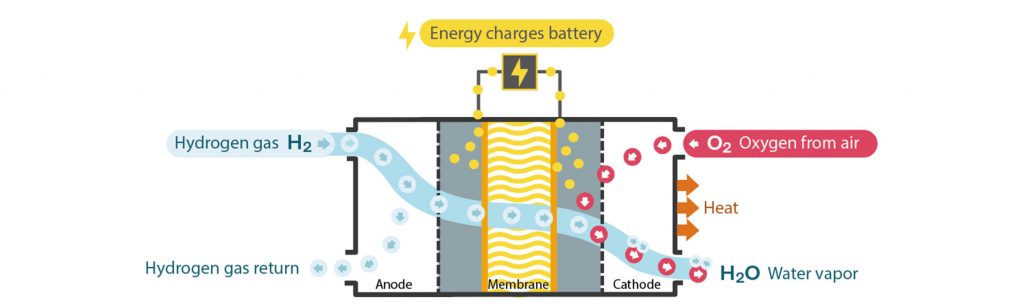

Simply put, fuel cells work by combining hydrogen with oxygen, with the resulting chemical reaction producing electricity. The process is completely emission-free, with the only by-product being water vapor. In principle, a fuel cell works much like a battery, except that it generates its own electricity from the hydrogen on-board rather than being charged from an external source. This means it can deliver longer driving ranges, and therefore is more feasible for long-haul transportation and heavier equipment.

An added benefit of hydrogen fuel cell solutions, is that they will also be free from the traditional machinery noise pollution. Without a combustion engine, hydrogen powered machines will be comparable to the low noise levels of the electric compact machines.

The Fuel Cell Test Lab is a demonstration of the same dedication to hydrogen fuel cell technology, as the recent launch of cell centric, a joint venture by Volvo Group and Daimler Truck to accelerate the development, production and commercialization of fuel cell solutions within long-haul trucking and beyond. Both form a key part of the Group’s overall ambition to be 100% fossil free by 2040.