Groundforce equipment has played a crucial role in the construction of a new extension to University Hospital, Limerick, in Ireland.

The new 9,800m2 acute ward, is built over the existing emergency department and dialysis unit and consists of 96 ensuite single rooms over four floors.

As part of the project, main contractor Sisk was required to build a new lift core, adjoining the existing hospital building and lower-level car park, to service the new structure.

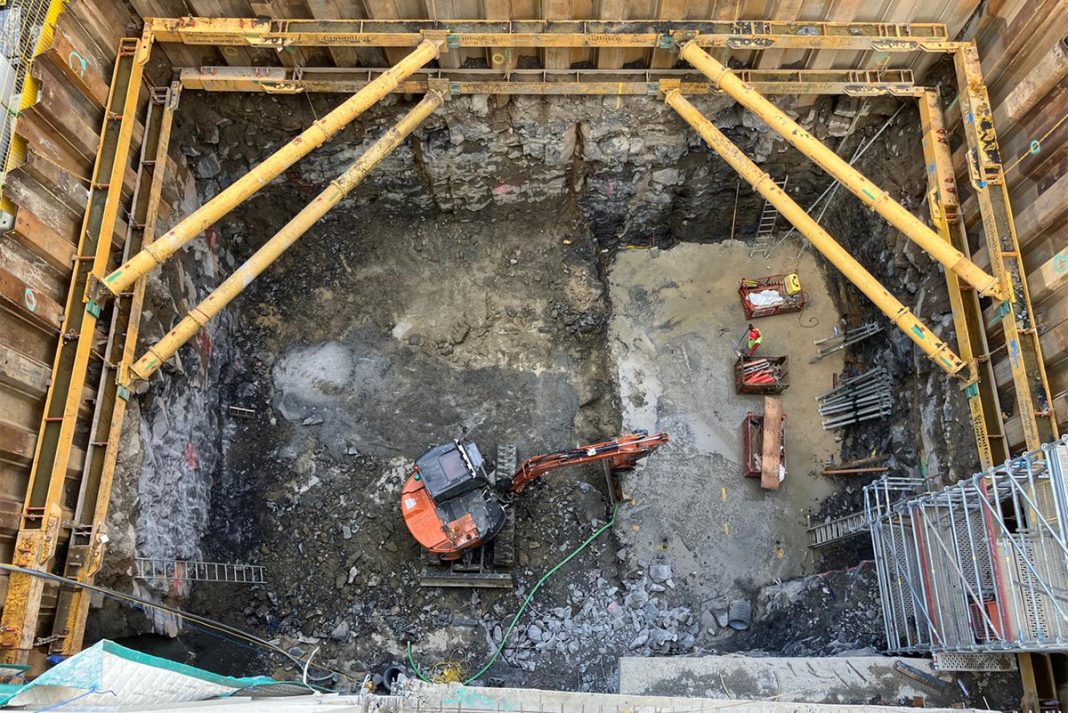

The lift core rises from an 8m-deep excavation dug immediately adjacent to the existing building. The bottom 4m of this excavation was in the bedrock, comprising a hard granite material, and was self-supporting. The upper 4m was in the overlying soil and required temporary support to prevent any collapse.

This was the element of the project that required the services of Groundforce.

“The excavation needed temporary support on three sides – the fourth side was the wall of the existing hospital building,” explains Groundforce director Joseph Lenihan.

The usual method employed by Groundforce is to support the sheet-piled retaining walls with modular extendable waling beams around the perimeter and hydraulic props spanning the excavation from side to side and bearing on the waling beams.

However, the size of this excavation (measuring approximately 14m x 17.5m) and its location against the wall of an existing building required a different approach.

“It was acceptable to the client for the adjoining wall to take a shear load from the shoring system but not a point load,” says Joseph Lenihan, “Therefore the shoring system had to rely on lateral restraint from the adjacent ground.”

The shoring system comprised two levels of Mega Brace frame supporting the 5m-long Larssen L603 sheet piles lining the excavation and four of Groundforce’s MP150 modular hydraulic props installed as corner struts at the end of the excavation furthest from the hospital building.

Groundforce also supplied the MS4 piling hammer to install the sheet-piles. Perimeter safety was provided in the form of Groundforce’s Edgesafe barrier and davit-arm rescue system.

The lateral loads from the three braced sides of the excavation were transferred along the line of the sheet-piled retaining walls which, together with the earth behind them, provided a shear key to prevent any point load transferring to the adjacent building.

The shoring system design was developed jointly by Groundforce and Sisk’s temporary works department and approved by the project’s consulting engineer, Arup.

“During the design stage a concern was raised by the Sisk design team regarding the transfer of the load to the shear key,” says Joseph Lenihan. “A typical hydraulic bracing system is pressurised to prevent any lateral movement. However, this lack of movement would not allow the shear key to take effect – the adjacent ground would not be given the chance to take the load.

“The solution was to not lock-off the ram element of the frame, thereby allowing it to contract once the system became loaded. This allowed a certain amount of movement and ensured that no point load was transferred to the adjacent wall.

“It’s fair to say that we’ve never done this before,” he adds.

The unique requirements of this operation demanded close collaboration between designers from Groundforce and Sisk’s temporary works department.

“There was a lot of design development required, not just for the shoring system itself but for the sequence of its installation and removal,” says Sisk’s project manager Stephen Geraghty.

“In fact, almost as much design went into the removal of the temporary works as for the installation. The sequence of backfilling to a certain level, concreting and removing the bracing had to be carefully planned,” he adds.

Carrying out the work so close to the existing building brought the added risk of disturbance to the hospital’s staff and patients. Noise and vibration therefore had to be kept to the absolute minimum and was carefully monitored.

“When it came to excavating through the rock we had to bring in a specialist to drill it out in small sections instead of going in there with heavy machinery. The excavation was quite slow: the first two or three weeks were spent just drilling/hydraulic breaking rock,” says Stephen Geraghty.

During the works, weekly design workshops ensured that the temporary works element remained under scrutiny.

“It was certainly tricky. But we kept in constant dialogue with Groundforce and I can’t complement them enough,” he adds.